GS3 panels are produced with the foamed-in place process, where two chemicals are injected under pressure between tow metal skins to form Polyurethane insulation panels. Chemical reaction produces high heat and high pressure during curing. Pressure of over tons is applied to the panel resulting in high structural strength, high density and thus high insulation value of the polyurethane panel.

GS3 panels come in standard size but can be custom

PANELS

DETAILS

SIZE

TYPES

SPECIFICATION

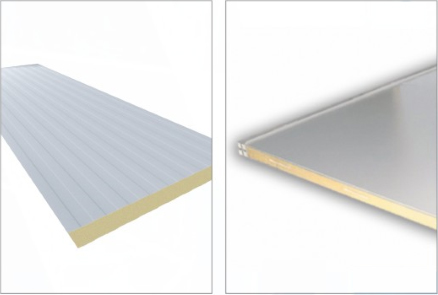

RIBBED / FLAT PANEL

- Panel Thickness (mm) : 50 – 60 – 80 – 100 – 120 – 150

- Panel Density : 40+2 kg / m3

- Pattern Ribbed : Flat

- Insulation : PUF

- Skin Thickness (mm ) : 0.50 mm -1.2 mm

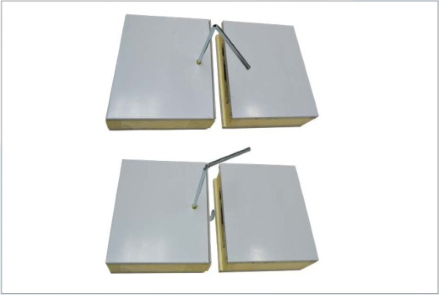

CAM LOCK

Cam lock is custom designed and manufactured as per specification. It is made from high impact plastic with rust resistance GI steel, during the foamed – in – place process, the locks are embedded every 800 mm for the wall panels and every 400 mm fir corner joints panels. During the installation, a hexagon Allen key is used to latch the male and female eccentric locks together.

APPLICATION OF GS3 SANDWICH PANELS

- Cold Storage / Cold Rooms

- Clean Rooms

- Operation Theaters

- Environmental Chambers

- Stability Chambers

- Pre fabricated structures

- Lift able cabins

- Site offices

- Lab our hutments

- Double storey structure

- Main Control Room

- Prefab villas / Cottages

- Sample Flat / Marketing Office Security / Guard huts

- Prefab Go downs / Canteen

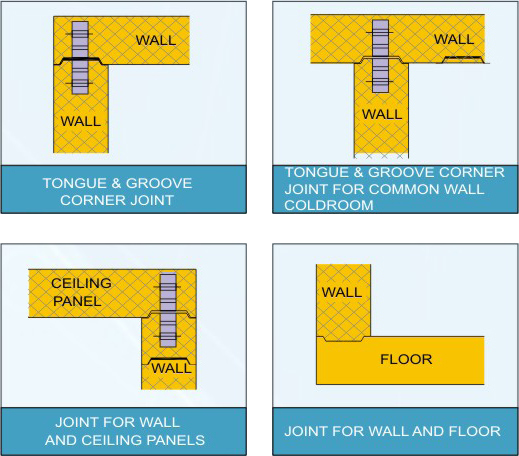

JOINTINGS

Copyright © 2018 GS3 Engineering Solutions. | Design By Spartan